From agriculture to auto parts, our plastic pallet boxes offer full-spectrum solutions—foldable, vented, lidded, heavy-duty, and insulated containers. Designed for high-load efficiency and space-saving logistics, all models support structural customization and are built for tough industrial use, direct from our manufacturing lines.

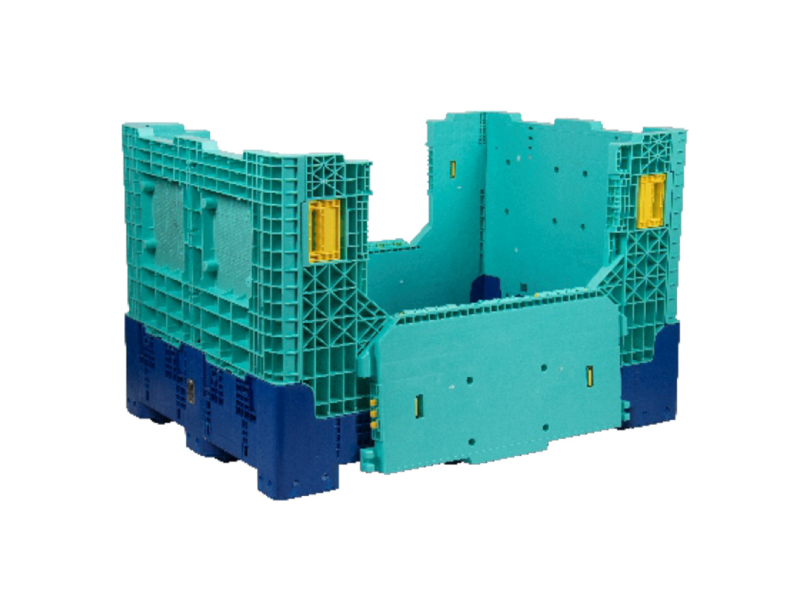

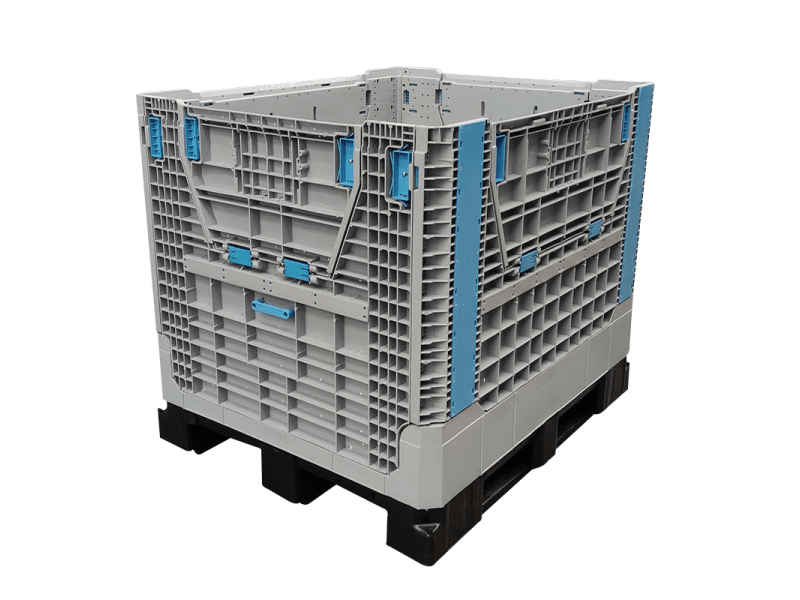

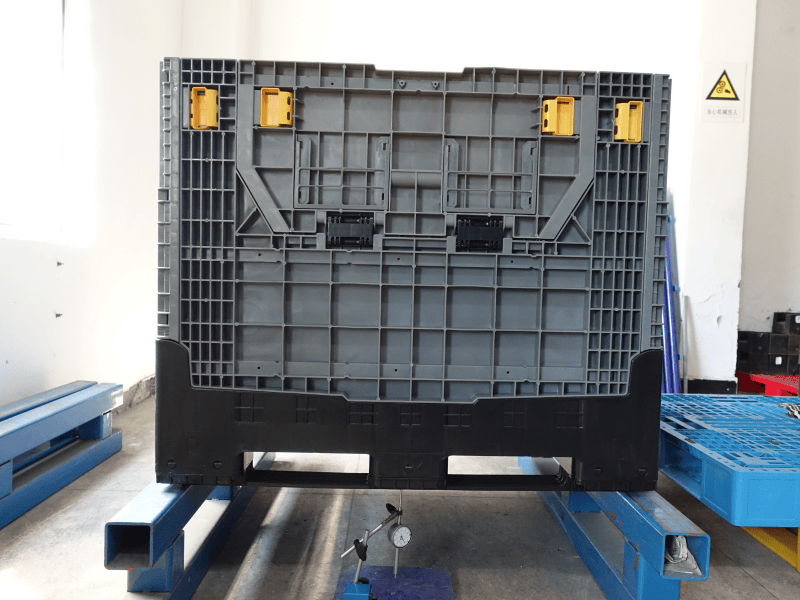

Ideal for businesses managing return logistics or seasonal storage, our collapsible pallet boxes combine strength with flexibility. Each unit folds flat in seconds, reducing backhaul costs and warehouse space. Designed with durable hinges and reinforced walls, they’re a reliable choice for closed-loop systems and export packaging.

Ideal for businesses managing return logistics or seasonal storage, our collapsible pallet boxes combine strength with flexibility. Each unit folds flat in seconds, reducing backhaul costs and warehouse space. Designed with durable hinges and reinforced walls, they’re a reliable choice for closed-loop systems and export packaging.

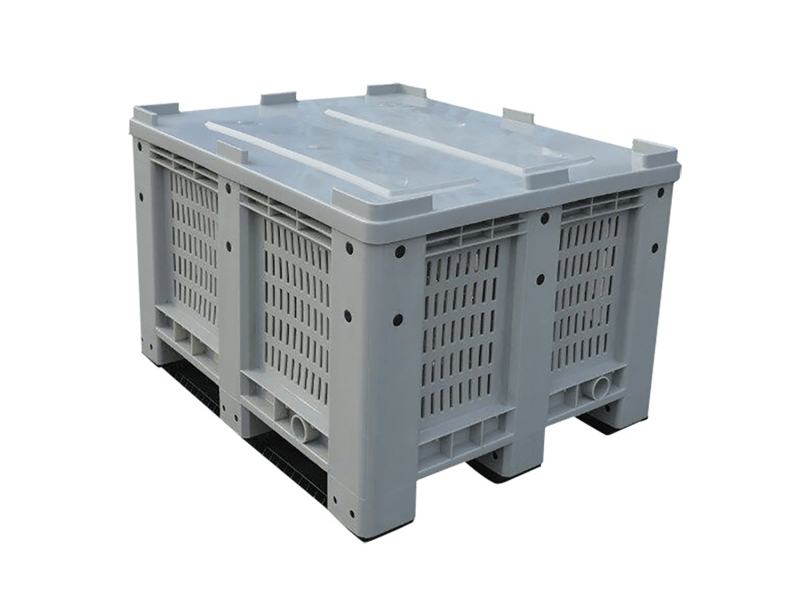

Designed with perforated sidewalls, our vented pallet boxes promote airflow and drainage—perfect for fruits, vegetables, seafood, and wet goods. The ventilated structure ensures faster cooling and reduces moisture buildup, helping maintain product quality from harvest to retail.

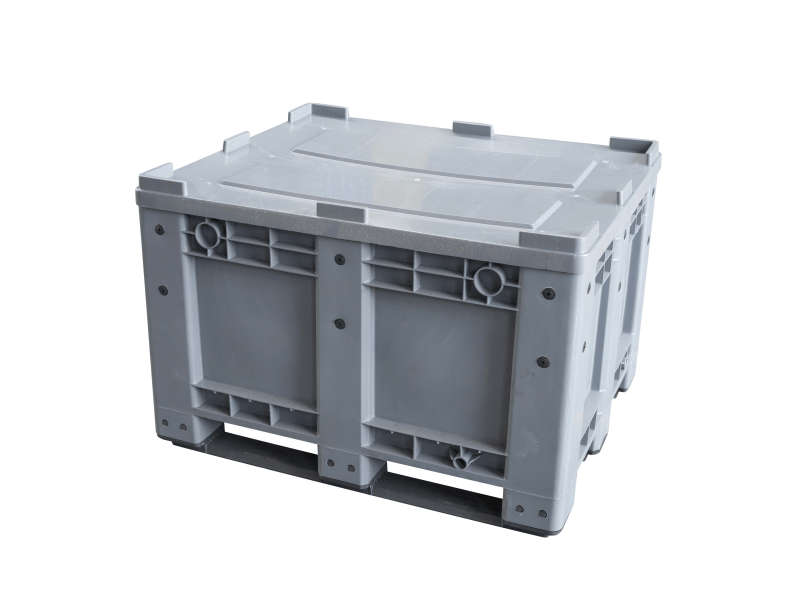

Our solid wall pallet boxes offer leak-proof containment and maximum content protection, ideal for bulk powders, resins, or sensitive parts. With seamless construction and impact-resistant design, these boxes excel in manufacturing, chemical processing, and food ingredient handling.

For cold chain and thermal-sensitive applications, our insulated bulk containers ensure stable internal temperatures and structural strength. Ideal for seafood processing, dairy transport, or pharmaceutical logistics, these rotomolded boxes offer dual-wall insulation and tight-seal lids to preserve freshness and reduce spoilage.

For cold chain and thermal-sensitive applications, our insulated bulk containers ensure stable internal temperatures and structural strength. Ideal for seafood processing, dairy transport, or pharmaceutical logistics, these rotomolded boxes offer dual-wall insulation and tight-seal lids to preserve freshness and reduce spoilage.

We tailor outer sizes, inner volumes, and wall thickness to fit your loading and stacking needs. Choose solid or vented walls, single or double height, and reinforced corners—fully compatible with automation systems and robotic handling lines.

Optional hinged lids, drop doors, or locking covers help users access goods easily while keeping contents secure. We design lid types based on your stacking height, sealing needs, and loading method—manual or forklift.

We offer multiple base styles—3-runner, 6-runner, 9-feet, and reinforced pipe—to support all forklift systems. Bases can be open or closed, with anti-slip feet or steel reinforcement for automated lines or heavy static loads.

We support custom logo molding, surface printing, RFID inserts, and barcode label areas to streamline your internal tracking. Color matching and code-based paneling are available for product separation across regions or categories.

Our plastic bulk containers outperform traditional materials in durability, hygiene, and cost-efficiency—ideal for modern warehouse and transport systems.

Plastic bulk containers offer seamless compatibility with forklifts, conveyors, and stacking systems. Unlike wood or metal boxes, they resist moisture, bacteria, and impact damage—ensuring clean, stable, and automation-ready handling across industries.

Our containers are reusable for hundreds of cycles without warping or corrosion. Compared to cardboard and steel boxes, they reduce repair, replacement, and disposal costs—delivering real savings across transport, storage, and returns.

Every batch of our plastic bulk containers undergoes strict in-house testing before shipment. From drop impact to stacking load, Enlightening Pallet replicate real-use conditions to ensure product strength, safety, and consistency across all warehouse and transport environments.

100% of boxes tested for drop resistance before bulk packing.

Vertical stacking tested under 3x dynamic load for warehouse safety.

Material aging tested in -30°C to +40°C for cold chain use.

Each batch includes traceable inspection and loading test reports.

Our MOQ is 50 units for collapsible models and 40 units for rigid types. For custom colors or printed logos, please contact us for specific MOQ requirements.

Yes. All our plastic pallet boxes comply with SGS, ISO9001, REACH, FDA, ROHS, CE, and UN standards. Additional testing like EN-840 or CTT can be arranged based on your destination market.

We accept Alibaba Trade Assurance, T/T, L/C, Paypal, and West Union. Flexible terms can be discussed based on order size and cooperation level.

We ship globally, with major clients in South America, Europe, the Middle East, Southeast Asia, and Australia. Custom documentation support is available for international logistics.

Absolutely. We offer full customization on dimensions, colors, lids, access doors, and branding. Custom mold solutions are also available for large volume orders.

Contact Us Online

Receive a response within one business day. Please look out for emails from “grace@icnplast.com” to ensure timely and efficient communication.

Receive a response within one business day. Please look out for emails from “grace@icnplast.com” to ensure timely and efficient communication.