Our Quality Control

From raw material inspection to finished product testing, Enlightening Pallet control every step in-house to ensure stable quality and long-term performance.

Quality Control Process

Certified Raw Material Sourcing for Stable Pallet Quality

We work closely with long-term suppliers to source virgin HDPE and PP for reusable pallets, and qualified recycled blends for export-use or disposable models.

Every material batch undergoes incoming inspection, with sampling protocols and recorded test data archived for traceability. For food-grade or export-grade products, we track material origin using certificate-linked labeling systems.

We also implement a formulation control process, ensuring the ratio of virgin to recycled resin meets structural and safety standards across different product lines.

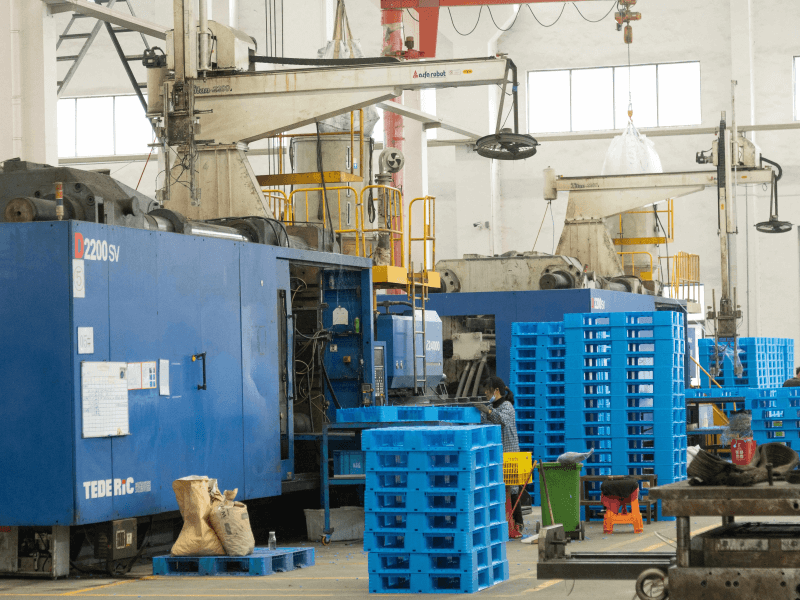

Process Control Ensured by Calibrated Equipment and Records

Our production runs on fully-calibrated injection and rotomolding machines, with real-time monitoring of pressure, temperature, and cycle time.

Each mold is maintained under a usage-lifetime tracking system, ensuring precision in every batch. Daily in-line inspections are conducted by trained QC staff to detect early deviations.

We maintain equipment logs and deviation reports, helping us trace, adjust, and prevent issues before they affect product performance.

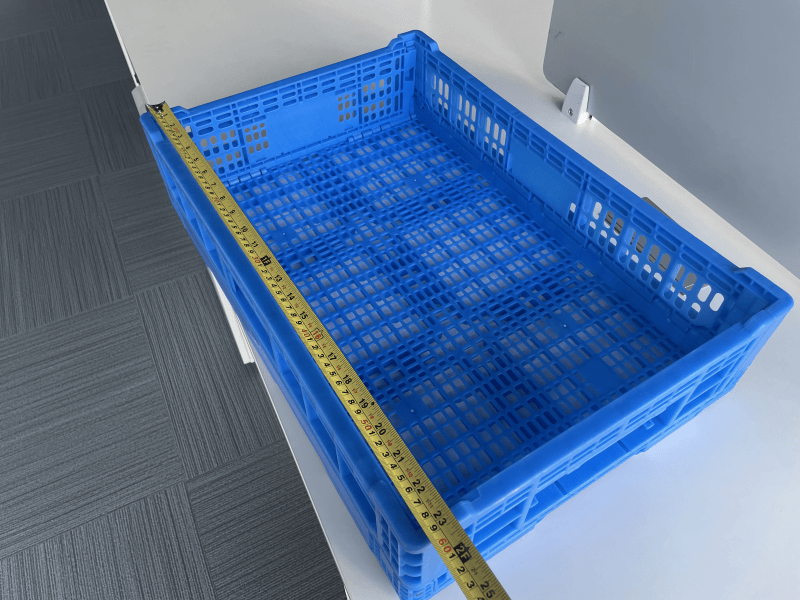

Dimensional and Performance Testing Before Every Shipment

Each finished pallet, bin, or crate is inspected for dimensional accuracy using calibrated gauges and mold references.

We conduct load tests, drop impact tests, and cold resistance checks to verify structural strength, especially for racking and export-grade products.

Before shipment, our QC team documents all inspection results and links them to the production batch—ensuring traceability and consistency across orders.

Dimensional and Performance Testing Before Every Shipment

We conduct standardized mechanical tests to ensure strength, durability, and handling safety across all product lines.

Static Load Test – ISO 8611-1

Dynamic Load Test – ISO 8611-1

Drop Test – ASTM D5276

Fork Entry Test - ISO 8611

Final Inspection and Certification for Every Export Shipment

Before dispatch, every product batch undergoes a final QC check and is linked to full documentation. We support compliance for global export standards with certified records and traceable production data.

Final QC Check

We inspect every unit for surface finish, dimensions, and label accuracy before packing—no visual defect or molding flaw leaves our factory.

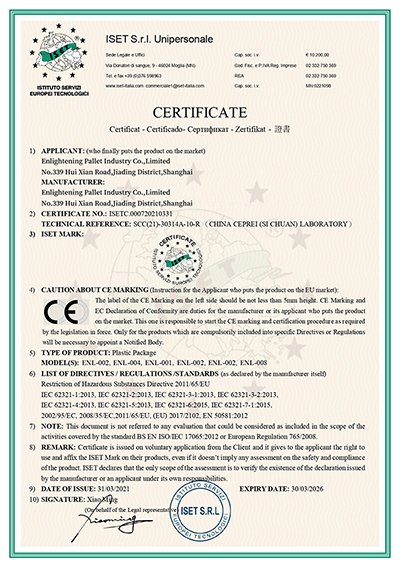

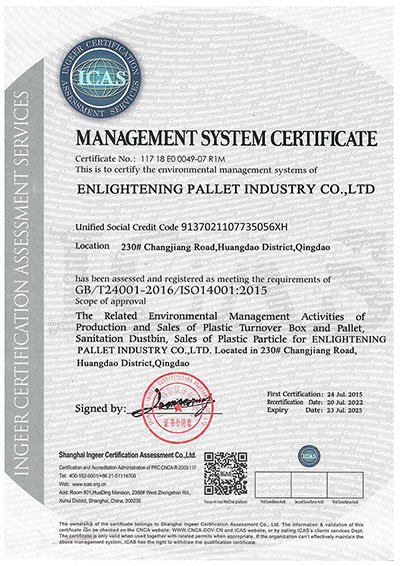

Export Certification Ready

We provide SGS, ISO, REACH, and food-grade certificates on request, tailored to your country’s requirements and product usage scenario.

Batch Traceability

Every product is marked with a unique production ID, allowing fast access to its inspection records and supporting documents for customs clearance.