1.Introduction: The Role of Plastic Pallets in Logistics, Storage, and Transportation

In the complex ecosystem of logistics, storage, and transportation, the efficiency and reliability of operations are paramount. Plastic pallets, with their robust design and versatile functionality, have emerged as a cornerstone in this environment, supporting businesses in achieving operational excellence. Their impact is profound, spanning various aspects of the supply chain.

Logistics: Enhancing Efficiency and Sustainability

In logistics, the seamless movement of goods from point A to point B is critical. Plastic pallets play a pivotal role in this process, offering a durable and lightweight solution that can significantly reduce transportation costs and carbon emissions. Their uniform size and shape facilitate easier handling and stacking, improving warehouse and transportation efficiency. Moreover, their resilience against weather and chemical exposure ensures the integrity of goods during transit, minimizing the risk of damage and loss.

Storage: Maximizing Space and Maintaining Quality

For storage applications, plastic pallets provide an optimal solution by maximizing warehouse space and enhancing the safety of stored goods. The design of plastic pallets, including options for stackable and rackable models, allows for better utilization of vertical space. This capability is crucial for businesses looking to expand storage capacity without the need for additional square footage. Additionally, the material properties of plastic pallets prevent the absorption of moisture, chemicals, and other contaminants, maintaining the quality and hygiene of the stored products, especially critical in food, pharmaceutical, and cleanroom environments.

Transportation: Reliability Across Distances

When it comes to transportation, the strength and durability of plastic pallets ensure that they can withstand the rigors of long-distance hauling, frequent loading and unloading, and varied environmental conditions. Unlike wooden pallets, which may splinter, crack, or rot, plastic pallets maintain their structural integrity over time, providing a reliable platform for the secure transportation of goods. Their compatibility with automated handling systems and standard transportation dimensions further streamlines the logistics process, reducing manual labor and enhancing overall supply chain efficiency.

The adoption of plastic pallets within logistics, storage, and transportation sectors underscores a commitment to operational efficiency, product safety, and environmental sustainability. By leveraging the unique benefits of plastic pallets, businesses can achieve a competitive edge, ensuring that their operations are not only more efficient but also aligned with global sustainability goals. As the supply chain landscape continues to evolve, the role of plastic pallets in supporting seamless and sustainable operations will undoubtedly grow, marking them as an indispensable tool in the modern business arsenal.

2.Exploring the Spectrum of Plastic Pallets: A Guide to Selecting the Right Type

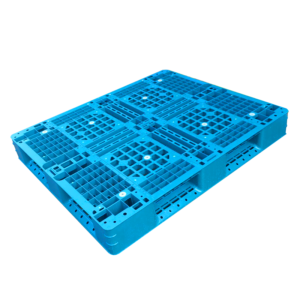

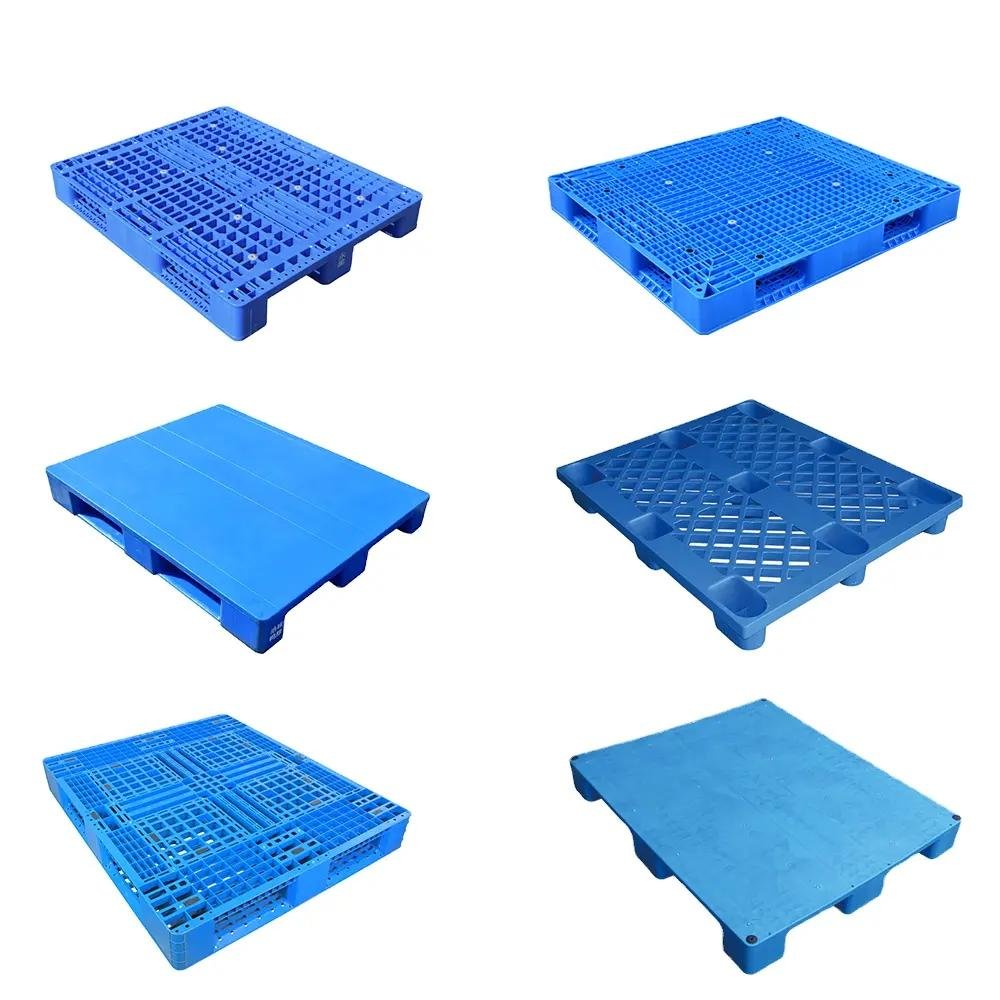

The versatility of plastic pallets makes them ideal for a wide range of applications across different industries. These pallets can be classified based on their intended use or design features, each type catering to specific operational needs and handling requirements.

Classification Based on Use

- Rackable Plastic Pallets

- Designed for use in racking systems, rackable pallets are engineered to support heavy loads while elevated. They offer excellent stability and durability, making them suitable for dynamic and static storage applications. Their design typically includes reinforcements to prevent sagging under load.

- Stackable Plastic Pallets

- Stackable pallets are designed with a bottom deck that allows you to stack one pallet on top of another with goods in between, optimizing vertical storage space. This feature is particularly useful in warehouses and storage areas where floor space is at a premium.

- Hygienic Plastic Pallets

- Specifically designed for industries where hygiene is paramount, such as the food and pharmaceutical sectors. These pallets are easy to clean and sanitize, often made from food-grade plastic that resists moisture, mold, and pathogens.

- One-Way Plastic Pallets

- Ideal for export and single-use applications, one-way plastic pallets are lightweight and cost-effective. They are designed for shipments where the pallet will not be returned, offering a durable and reliable transport solution without the need for pallet exchange.

Classification Based on Shape

- 9 Legs Plastic Pallets

- Feature nine legs providing stability and support. These pallets are often nestable, saving significant space when not in use or during return transport, making them a cost-effective and space-saving option for many operations.

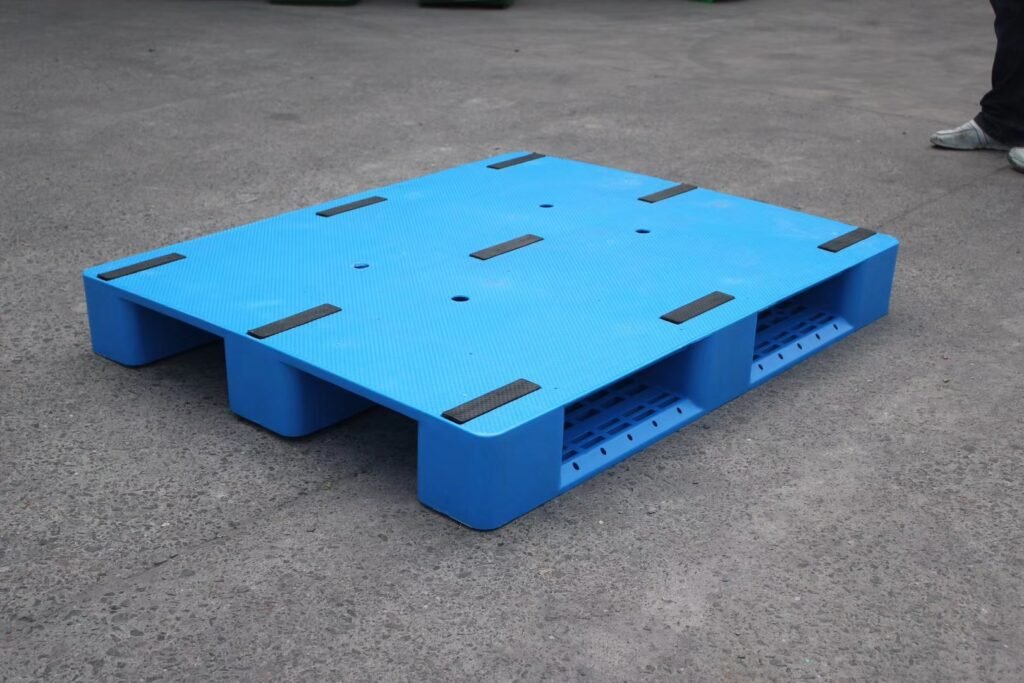

- 3 Skids Plastic Pallets

- Equipped with three longitudinal skids, these pallets are designed for enhanced strength and durability. The skids provide additional support for heavy loads and improve the pallet’s compatibility with conveyor systems and forklift handling.

- Full Perimeter Plastic Pallets

- Have a perimeter base that offers maximum stability and is ideal for heavy-duty applications. The full perimeter design allows for even distribution of weight and supports higher load capacities, making them suitable for high-rack storage.

- Reversible Plastic Pallets

- Can be used on both sides, increasing their versatility and lifespan. Reversible pallets are particularly useful in applications where the pallet needs to be flipped for access to goods from either side.

Specialized Use Pallets

- Spill Control Pallets

- Designed to contain spills, these pallets are ideal for transporting and storing hazardous materials. They typically feature a sump area to catch and contain leaks, preventing contamination of the warehouse floor or environment.

- Water Bottle Pallets

- Tailored for the beverage industry, these pallets are designed to securely hold water bottles during transport and storage. Their specific design minimizes the risk of product damage and ensures the efficient handling of bottled goods.

Each type of plastic pallet offers unique benefits tailored to different industrial needs, from enhancing storage efficiency and maintaining hygiene standards to ensuring the safe transport of goods. Understanding the specific requirements of your operation will guide you in selecting the most appropriate plastic pallet type, thereby optimizing your supply chain management.

3.Choosing the Right Material for Plastic Pallets: A Comparative Analysis

When selecting the optimal material for plastic pallets, understanding the strengths and limitations of each option is crucial. This decision impacts not only the durability and lifespan of the pallets but also their suitability for different industries and applications. Here’s a breakdown of the most common materials used in plastic pallet manufacturing, alongside traditional wood and metal options.

Virgin (New) Material

- Pros: Pallets made from virgin materials exhibit superior strength and durability. They are less likely to crack or warp under heavy loads or in extreme environmental conditions. This makes them ideal for high-demand or regulated industries such as food and pharmaceuticals, where hygiene and reliability are paramount.

- Cons: The primary downside is cost. Virgin material pallets are more expensive than those made from recycled materials, making them less cost-effective for one-way shipping or non-returnable applications.

Recycled Material

- Pros: Pallets manufactured from recycled plastics offer a more environmentally friendly and cost-effective solution. They appeal to businesses looking to reduce their carbon footprint and operational costs. Recycled material pallets are suitable for many standard applications, especially where pallet return systems are in place.

- Cons: The variability in the quality of recycled materials can affect the consistency and longevity of the pallets. They may also be less suited for applications requiring direct food contact unless specifically treated or certified.

Wood Pallets

- Pros: Wood pallets are widely used due to their low initial cost and ease of repair. They are versatile and can be custom-built to various specifications, accommodating a wide range of weights and sizes.

- Cons: The main disadvantages include susceptibility to moisture, mold, and pests, which can compromise the integrity of the goods being transported. Wood pallets also require more maintenance and have a shorter lifespan compared to plastic pallets.

Metal Pallets

- Pros: Metal pallets, typically made from aluminum or steel, offer the highest level of durability and are ideal for heavy or high-value loads. They are fireproof and not susceptible to pests, making them suitable for long-term outdoor storage.

- Cons: The significant drawbacks are the higher initial cost and the weight of metal pallets, which can increase shipping costs. Additionally, metal pallets are not as easily repaired as wood pallets and can cause damage to goods if not properly handled.

Choosing the right material for your pallets requires a thorough evaluation of your specific needs, including the nature of the goods being handled, the conditions under which they will be transported and stored, and the overall goals of your supply chain. By understanding the unique benefits of plastic pallets, businesses can optimize their operations for efficiency, safety, and environmental sustainability.

4.Size and Design Considerations for Plastic Pallets: Tailoring to Your Needs

When it comes to optimizing your supply chain with plastic pallets, understanding the nuances of their various sizes and designs is key. Each type and size offers distinct advantages tailored to specific logistics requirements, ensuring that your goods are transported and stored efficiently, safely, and economically.

Variety in Sizes: Maximizing Efficiency and Compatibility

- Standard Sizes: The most commonly used pallet sizes are designed to fit standard shipping containers and trucks, minimizing wasted space and optimizing load efficiency. For example, the widely adopted 48″ x 40″ pallet is ideal for maximizing the use of space in standard shipping containers.

- Custom Sizes: For specialized goods or unique storage systems, custom-sized pallets ensure that products fit perfectly, reducing the risk of damage during transport and making the best use of available storage space.

Design Features: Addressing Specific Requirements

- Nestable Pallets: These pallets are designed to nest inside each other when not in use, significantly reducing storage and return shipment space requirements. They are particularly beneficial for operations where space efficiency is a priority.

- Rackable Pallets: Featuring reinforcements for added strength, rackable pallets are optimized for use in racking systems, supporting heavy loads while elevated. This design is crucial for warehouses that utilize vertical storage.

- Hygienic Pallets: With smooth, easily cleanable surfaces, hygienic pallets are designed for industries where cleanliness is paramount, such as food processing and pharmaceuticals. These pallets help in maintaining stringent hygiene standards.

- Specialty Pallets: Tailored for specific applications, such as spill containment or the transport of unique items (e.g., drums, bottles), specialty pallets address the particular needs that standard pallets cannot.

Advantages Across the Board

The strategic selection of pallet sizes and designs can lead to numerous operational benefits:

- Enhanced Safety and Product Protection: Customizable features, such as anti-slip surfaces and edge racking capabilities, ensure that goods are securely transported and stored, minimizing the risk of accidents and damage.

- Improved Storage Efficiency: By choosing pallets that are stackable, nestable, or designed for specific racking systems, businesses can significantly increase their storage capacity without expanding their footprint.

- Cost Reduction: Optimal pallet size and design selection can lead to lower transportation and storage costs by maximizing space utilization and reducing the need for additional handling.

- Compliance and Sustainability: Selecting the right pallet design can also assist in meeting industry regulations and sustainability goals, particularly when using recyclable materials and designs that minimize environmental impact.

5.Pallet Durability and Maintenance: Ensuring Longevity with Plastic Pallets

Plastic pallets have become the go-to choice for many industries due to their exceptional durability, longevity, and low maintenance requirements. Unlike their wood and metal counterparts, plastic pallets offer significant advantages in resisting environmental factors that typically degrade other materials.

Superior Durability

The composition of high-density polyethylene (HDPE) or polypropylene (PP) makes plastic pallets extremely durable. These materials are known for their strength and resilience, allowing plastic pallets to withstand heavy loads and repetitive use. Unlike wood pallets, which may splinter or break under heavy stress, plastic pallets retain their integrity over time, ensuring consistent performance and reliability in demanding logistics environments.

Resistance to Environmental Factors

One of the standout features of plastic pallets is their inherent resistance to moisture, pests, and chemicals:

- Moisture Resistance: Plastic pallets do not absorb water, which is a common issue with wood pallets. This resistance to moisture prevents the growth of mold and fungi, making plastic pallets ideal for use in humid or wet conditions.

- Pest Resistance: Wood pallets often require treatment to prevent infestation by pests such as termites and beetles. In contrast, plastic pallets are naturally resistant to pests, eliminating the need for chemical treatments and reducing the risk of contamination.

- Chemical Resistance: Plastic pallets are impervious to many chemicals, including acids, alkalis, and solvents. This makes them suitable for transporting and storing a wide range of goods, including hazardous materials, without risk of degradation.

Low Maintenance Requirements

The maintenance of plastic pallets is minimal compared to wood and metal alternatives. Their smooth surfaces and resistance to contaminants mean that they can be easily cleaned and sanitized, a crucial advantage for industries where hygiene is a priority, such as food and pharmaceuticals. Additionally, the absence of nails, screws, and splinters in plastic pallets reduces the risk of injury to workers and damage to goods, further lowering the overall maintenance and operational costs.

Longevity and Cost-Effectiveness

The initial investment in plastic pallets is often higher than that of wood pallets. However, their extended lifespan—often lasting several years longer than wood pallets—translates to a lower total cost of ownership over time. The durability and low maintenance requirements of plastic pallets mean that they need to be replaced less frequently, providing significant cost savings and a better return on investment in the long run.

In summary, the durability, resistance to environmental factors, and low maintenance requirements of plastic pallets make them a highly efficient and cost-effective choice for a wide range of industries. By choosing plastic pallets, businesses can ensure the longevity of their logistics tools, maintain high standards of hygiene and safety, and achieve greater sustainability in their operations.

6.Procurement Strategies: Navigating Plastic Pallet Purchases

Making informed procurement decisions for plastic pallets involves a strategic approach that balances cost-effectiveness with quality and long-term value. Here are essential tips and considerations to guide your procurement process, including the nuances of buying versus renting, selecting the right supplier, and employing effective negotiation strategies.

Buying vs. Renting

- Buying: Purchasing plastic pallets outright is a significant upfront investment but can be cost-effective in the long run for operations with consistent and ongoing pallet needs. Ownership allows for complete control over the asset, making it suitable for businesses with specific customization requirements or those looking to capitalize on the long-term cost savings due to the durability of plastic pallets.

- Renting: Renting pallets may be a more viable option for businesses with variable demand, shorter-term projects, or those looking to reduce capital expenditures. Renting offers flexibility and can help manage costs effectively, but it’s crucial to consider the long-term rental fees, which can accumulate over time.

Supplier Selection Criteria

- Quality and Compliance: Ensure the supplier’s pallets meet industry standards and compliance requirements, especially for operations in food safety, pharmaceuticals, and international shipping.

- Sustainability Practices: Given the increasing focus on environmental responsibility, evaluate the supplier’s commitment to sustainability, including the use of recycled materials and recyclable products.

- Supply Chain Reliability: Assess the supplier’s ability to provide a stable supply of pallets, including their capacity to meet your demand spikes and their geographical coverage for timely deliveries.

- Customer Service and Support: Look for suppliers who offer robust customer service, including assistance with pallet management, recycling programs, and logistical support.

Negotiation Strategies

- Volume Discounts: If purchasing, negotiate volume discounts for bulk orders. Suppliers are often willing to offer favorable pricing to secure a large sale.

- Long-term Contracts: For renting, consider negotiating long-term contracts to lock in lower rates. Suppliers may offer attractive terms for the assurance of ongoing business.

- Value-added Services: Negotiate for value-added services such as delivery, pickup, and pallet management solutions. Including these services can enhance the overall value of the procurement contract.

- Flexibility and Scalability: Ensure the agreement includes terms that allow for adjustments in order volume based on your business needs, providing flexibility as your operations scale.

Making informed procurement decisions requires a deep understanding of your operational needs, thorough market research, and strategic negotiations. Whether buying or renting, the goal is to secure high-quality plastic pallets at competitive prices while ensuring they align with your logistical requirements and sustainability goals. By carefully selecting suppliers and effectively negotiating terms, businesses can optimize their plastic pallet procurement strategy for both cost-efficiency and operational excellence.

7.Vendor Analysis and Selection Criteria for Plastic Pallet Suppliers

Selecting the right plastic pallet supplier is crucial for ensuring the efficiency and reliability of your supply chain operations. Here are key factors to consider during the vendor analysis and selection process:

1. Cost Structures and Supplier Margins

- Understanding Cost Structures: Investigate how the supplier prices their pallets, including the breakdown of material, manufacturing, and transportation costs. This insight will help you assess the value for money and identify areas for potential cost negotiations.

- Supplier Margins: Gain clarity on the supplier’s profit margins. Suppliers with reasonable margins are often more stable and reliable but be wary of margins that seem either too high (indicating possible overpricing) or too low (suggesting sustainability or quality concerns).

2. Quality Assurance

- Material Quality: Ensure the pallets are made from high-quality materials, whether virgin or recycled, that meet your operational requirements for durability and performance.

- Certifications: Look for suppliers with pallets that have necessary certifications, such as ISPM-15 for international shipping, to comply with regulatory standards.

3. Sustainability Practices

- Environmental Responsibility: Evaluate the supplier’s commitment to sustainability, including their use of recycled materials and participation in recycling programs. Suppliers that prioritize environmental impact can align with your company’s CSR objectives.

4. Supply Chain Reliability

- Delivery Capabilities: Assess the supplier’s ability to deliver on time, including their logistical networks and capacity to handle your demand volumes. Reliability in fulfillment is key to maintaining smooth operations.

- Scalability: Consider whether the supplier can scale up their services to meet your growing needs. A good supplier should be able to support your business expansion without compromising on service quality.

5. Innovation and Product Range

- Product Innovation: Look for suppliers who invest in research and development to offer innovative pallet solutions, such as enhanced designs for better durability and efficiency.

- Product Range: A wide product range allows for more tailored solutions to fit different operational needs, from lightweight export pallets to heavy-duty rackable pallets.

6. Customer Service and Support

- After-Sales Support: Quality customer service, including responsive after-sales support and assistance with pallet management systems, reflects a supplier’s commitment to their clients.

- Technical Assistance: Suppliers who offer technical advice and assistance can be invaluable, especially when implementing new logistics solutions or troubleshooting issues.

7. Financial Stability

- Supplier’s Financial Health: A financially stable supplier is less likely to encounter disruptions that could affect your supply chain. Reviewing their financial performance and stability is a prudent step.

8. References and Reputation

- Industry Reputation: Research the supplier’s reputation in the industry, including customer testimonials and reviews. A positive reputation is a strong indicator of reliability and quality.

- Reference Checks: Speaking directly to current or past customers can provide insights into the supplier’s performance and reliability.

Selecting a plastic pallet supplier involves a comprehensive evaluation of these criteria to ensure that you partner with a provider who can meet your quality and service expectations. A thorough vendor analysis not only helps in identifying a supplier capable of supporting your operational needs but also fosters a long-term partnership that can contribute to the overall success and sustainability of your supply chain.

8.Navigating Global Standards

Understanding and complying with international pallet size standards is critical for businesses engaged in global trade. These standards ensure that pallets can be efficiently used and exchanged across different regions and logistics systems, enhancing the overall efficiency of the supply chain.

International Pallet Size Standards

International pallet size standards were developed to facilitate the easy transport and storage of goods in a variety of settings, including shipping containers, trucks, and warehouses. Some of the most recognized standards include:

- ISO Standards: The International Organization for Standardization (ISO) specifies six pallet dimensions, widely accepted worldwide to improve the compatibility of pallets in international logistics.

- European Pallet Association (EPAL) Pallets: The EPAL oversees the standardization of Euro pallets, which are among the most used in the world, especially in Europe. The standard Euro pallet size is 800mm x 1200mm.

- North American Pallet Sizes: The most common pallet size in North America is the 48″ x 40″ pallet, also known as the Grocery Manufacturers Association (GMA) pallet, which is widely used in many industries across the continent.

Navigating Global Standards for Efficiency

To ensure compliance and efficiency in logistics operations, businesses should:

- Identify Relevant Standards: Determine which international pallet standards are most relevant to your supply chain. This may depend on your industry, the nature of the goods you’re shipping, and your key markets.

- Choose Standardized Pallets: Whenever possible, use pallets that conform to international standards. This can greatly reduce the complexity of shipping goods internationally, as these pallets are designed to fit into standard shipping containers and trucks, and be easily handled by pallet jacks and forklifts around the world.

- Consider Modular Design: Using pallets that are modular to shipping container dimensions can maximize space utilization. For instance, selecting a pallet size that allows for two pallets to be placed side by side in a container can optimize shipping efficiency.

- Stay Informed on Regulations: Keep abreast of any changes in international shipping and pallet regulations that might affect your operations. This includes staying informed about phytosanitary requirements for wood packaging, which can impact the choice between wooden and plastic pallets.

- Leverage Supplier Expertise: Work with pallet suppliers and logistics providers who have expertise in international standards and can offer pallet solutions that meet these requirements while optimizing your supply chain performance.

By carefully navigating these international standards and making informed decisions about pallet selection, businesses can ensure their products move smoothly and efficiently across global supply chains, reducing costs and improving delivery times.

Selecting the right plastic pallets for your business is more than just a procurement decision; it’s a strategic choice that influences the operational efficiency, safety, and sustainability of your supply chain. The journey through understanding the different types of plastic pallets, their materials, sizes, designs, durability, and maintenance requirements underscores the significance of making informed choices that align with your business needs and goals.

Operational Efficiency: By choosing pallets that fit the specific requirements of your products and logistics operations, you can streamline processes, reduce handling times, and maximize storage space. The adaptability of plastic pallets to various logistics scenarios—from warehousing to international shipping—ensures that your products move through the supply chain more smoothly and efficiently.

Safety: The inherent features of plastic pallets, such as their durability and resistance to moisture, pests, and chemicals, minimize the risk of product contamination and damage. Moreover, their consistent quality and lack of protruding nails or splinters reduce workplace injuries, making your operations safer for employees.

Sustainability: Opting for plastic pallets, especially those made from recycled materials, aligns with environmental sustainability goals. Their long lifespan and recyclability reduce waste and the need for frequent replacements, contributing to a more sustainable supply chain that minimizes your company’s environmental footprint.

In conclusion, the selection of plastic pallets impacts far beyond simple logistics; it reflects your company’s commitment to efficiency, safety, and environmental responsibility. By carefully considering your options and choosing wisely, you position your business for success in today’s competitive and fast-paced market, ensuring that your operations are not only efficient and safe but also sustainable for the future.