In industries where liquid storage and handling are routine, spill containment is not just a safety measure—it’s a legal and operational necessity. A spill pallet plays a vital role in protecting workplaces, employees, and the environment by serving as a secondary containment system for drums, intermediate bulk containers (IBCs), and other hazardous containers.

What Is a Spill Pallet?

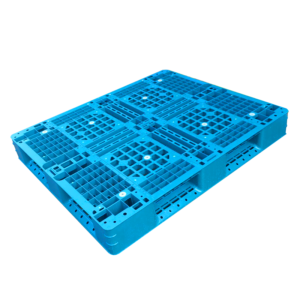

A spill pallet is an engineered platform designed to hold drums or containers while capturing any leaks or spills that may occur. Underneath the load surface lies a sump space that collects overflow, ensuring no liquids reach the surrounding floor. Commonly made from chemical-resistant polyethylene or durable galvanized steel, spill pallets offer exceptional strength, corrosion resistance, and reusability, making them ideal for repeated industrial use.

How Does a Spill Pallet Work?

Spill pallets function as a passive containment system. They provide a stable platform to store hazardous materials while passively catching any unintended leaks in the sump basin below. By design, compliant spill pallets must contain at least 110% of the volume of the largest container placed on them. Whether used with 200-liter drums, IBCs, or chemical tanks, they ensure regulatory and environmental safety.

Benefits of Using Spill Pallets

Implementing spill pallets into your operation offers multifaceted benefits:

Health & Safety: Prevent slip hazards and chemical exposure accidents in the workplace.

Environmental Protection: Safeguard soil, water systems, and surrounding areas from chemical contamination.

Regulatory Compliance: Meet OSHA, EPA, and international spill containment requirements.

Operational Efficiency: Minimize cleanup time and avoid costly downtime due to spill incidents.

Spill Pallets for Hazardous Material Handling

For companies dealing with corrosive, flammable, or toxic substances, spill pallets are indispensable. They offer a critical line of defense against unforeseen leaks, cross-contamination, and chemical reactions. Applications range from manufacturing plants to chemical warehouses, logistics centers, and marine terminals—anywhere that safe containment of liquids is mission-critical.

How to Select the Right Spill Pallet

Selecting a suitable spill pallet requires consideration of:

Container Type & Size: Match IBCs with IBC-compatible pallets; use drum-specific models for 55-gallon barrels.

Liquid Type: Consider chemical compatibility and flammability.

Material: Choose polyethylene for corrosives, or steel for flammables and high-impact environments.

Load & Sump Capacity: Ensure the pallet meets 110% capacity rules.

Environment: Select outdoor-compatible models for UV and weather resistance.

Spill Containment Regulations & Best Practices

Businesses must comply with spill control standards such as EPA SPCC, OSHA 1910.106, or regional equivalents. Regulations often specify containment capacity, labeling, and employee training. Regular risk assessments and emergency spill protocols are essential to maintaining compliance and workplace safety.

Maintenance: How to Clean a Spill Pallet

After each use, especially following a spill, the sump should be thoroughly cleaned:

Drain and dispose of collected liquid per hazardous waste regulations.

Use appropriate cleaning agents based on stored liquid type (e.g., neutralizing agents for acids)

Avoid chemical cross-reactions during the cleaning process.

Inspect for structural damage, cracks, or residue before reuse.

Conclusion

Spill pallets are more than a safety measure—they are a proactive investment in operational continuity and legal compliance. Whether your facility handles oil, solvents, acids, or flammables, the right spill pallet protects your people, products, and reputation. Partner with an experienced supplier to choose the most suitable containment solution for your operations.